In a stunning move that’s sent ripples through the automotive world, German luxury performance brand Brabus has officially announced plans to establish its first-ever manufacturing facility outside Europe. The company, renowned worldwide for transforming Mercedes-Benz vehicles into high-performance masterpieces, has selected Perth, Western Australia, as the location for its groundbreaking expansion.

The announcement came during an exclusive industry event where Brabus CEO Constantin Buschmann revealed the bold strategic shift that marks a new chapter in the company’s nearly 50-year history. This unprecedented move positions Australia as a pivotal hub in Brabus’s global operations and signals the brand’s commitment to the Asia-Pacific region.

Table of Contents

Strategic Location Opens New Markets

The decision to establish operations in Perth wasn’t made lightly. After an extensive two-year evaluation process examining potential locations across the Asia-Pacific region, Western Australia emerged as the clear frontrunner. The state’s combination of technical expertise, established automotive supply chains, and strategic positioning as a gateway to Asian markets proved irresistible.

“Australia represents the perfect balance of technical capability, logistical advantage, and proximity to key growth markets,” explained Buschmann during the announcement. The Perth facility will serve as both a manufacturing center and a strategic base for the company’s expansion throughout the Asia-Pacific region.

Industry experts note that this move could reshape the luxury automotive landscape in the region. With reduced shipping times and localized production, Brabus vehicles will become more accessible to wealthy clients across Southeast Asia and Oceania who previously faced lengthy waits for European imports.

Local Impact and Job Creation

The economic implications for Western Australia are substantial. The new facility, expected to be fully operational by mid-2026, will create approximately 350 direct jobs and hundreds more in supporting industries. These positions will range from highly-skilled engineering roles to manufacturing, logistics, and administrative positions.

Western Australia Premier Sarah Johnston called the announcement “a transformative opportunity” for the state’s manufacturing sector. “This investment represents a vote of confidence in our workforce and our position in the global economy,” Johnston stated at the press conference following the announcement.

The facility will be constructed on a 15-hectare site in the Henderson industrial area, approximately 25 kilometers south of Perth. The location provides excellent port access, critical for both receiving components and shipping finished vehicles throughout the region.

Training and Skill Development

A key component of the Brabus Australia strategy involves extensive training programs. The company has partnered with local technical colleges to develop specialized courses in advanced automotive manufacturing and customization techniques.

This focus on skill development aligns with the Western Australian government’s push to diversify the state’s economy beyond its traditional mining base. Education Minister Lisa Rodgers highlighted that “this partnership creates pathways for young Western Australians into high-value manufacturing careers.”

Initial training cohorts will include trips to Brabus headquarters in Bottrop, Germany, ensuring the company’s exacting standards are maintained at the new facility. These programs are expected to begin in early 2026 as construction of the facility nears completion.

Production Plans and Vehicle Offerings

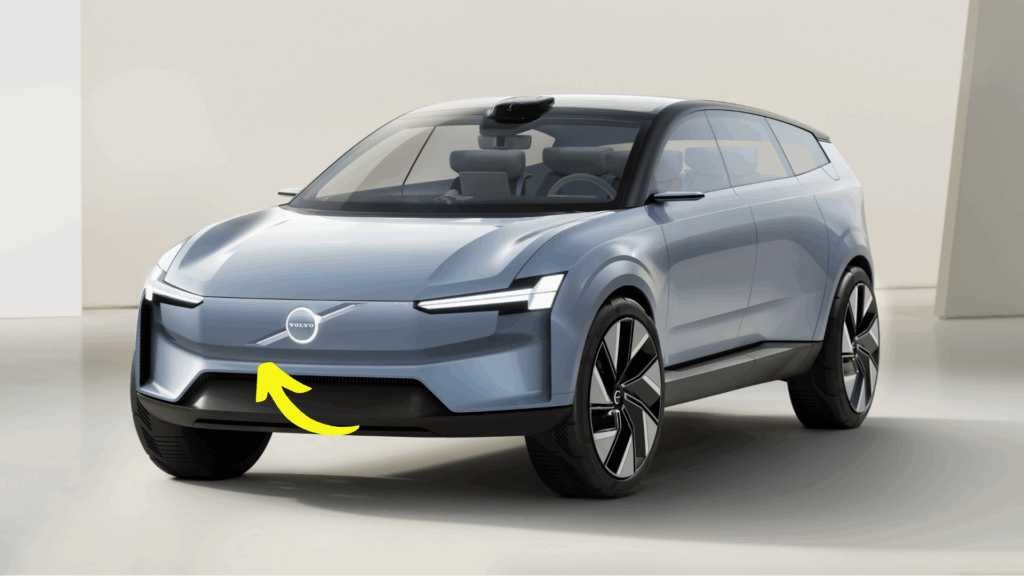

The Perth facility will initially focus on producing three key model lines: performance-enhanced versions of Smart electric vehicles, select Mercedes-Benz SUV models, and the company’s marine products.

The Brabus Smart #3 and #5 models are expected to be the first vehicles produced at the new facility, with production slated to begin in late 2026. These electric performance vehicles have already garnered significant interest in Australian and Asian markets, with their combination of zero-emission driving and Brabus-enhanced performance.

“Starting with our electric vehicle offerings makes perfect sense for the Australian market,” explained Thomas Müller, Brabus’s Director of International Operations. “We see tremendous potential for growth in this segment throughout the region.”

The facility will implement Brabus’s renowned manufacturing processes, which blend traditional craftsmanship with cutting-edge technology. Each vehicle undergoes extensive customization, from performance enhancements to bespoke interior treatments, reflecting the company’s commitment to personalized luxury.

Marine Division Expansion

In an interesting twist, the announcement also revealed plans for the Australian facility to serve as a hub for Brabus Marine operations in the Southern Hemisphere. The company’s high-performance boats have found a receptive market in Australia’s coastal communities.

“The boating culture in Australia aligns perfectly with our marine philosophy,” noted Buschmann. “Having local production capabilities will allow us to better serve this market while developing products specifically suited to regional conditions.”

This expansion of the marine division represents a significant diversification of Brabus’s Australian operations beyond traditional automotive manufacturing. Industry analysts suggest this could insulate the company from potential fluctuations in the automotive sector.

Also Read: GM Recalls 721K V8 Engines Worldwide, Australia Still Unclear

Technological Innovation and Sustainability

The new facility will not merely replicate existing Brabus operations but will incorporate several technological innovations. The company has committed to making the Perth plant its most advanced and sustainable manufacturing facility to date.

The facility design includes extensive solar power generation, water recycling systems, and energy-efficient manufacturing processes. These elements reflect both Brabus’s commitment to reducing environmental impact and the practical realities of operating in Western Australia’s climate.

“We’re designing this facility from the ground up to be as efficient and sustainable as possible,” explained Architectural Lead Sarah Chen. “This isn’t just about meeting current standards but setting new benchmarks for the industry.”

Beyond physical infrastructure, the facility will implement advanced digital manufacturing processes, including extensive automation and real-time quality control systems. These technological capabilities will ensure the Australian-made vehicles meet the same exacting standards as those produced in Germany.

Research and Development Center

Perhaps most intriguingly, the announcement included plans for a dedicated research and development center focused on electric vehicle performance technology. This center will collaborate with both Australian universities and Brabus’s German engineering teams.

“Australia has produced remarkable automotive engineering talent,” noted Dr. Markus Weber, Brabus’s Head of Research and Development. “We’re excited to tap into this expertise as we develop the next generation of electric performance vehicles.”

This R&D commitment suggests Brabus sees Australia as more than just a manufacturing location but as a genuine partner in future innovations. The focus on electric vehicle technology also indicates the company’s strategic direction as the automotive industry continues its electric transition.

Market Response and Industry Analysis

The announcement has generated significant buzz within the automotive industry, with shares in Brabus’s parent company seeing a modest 3.2% increase following the news. Industry analysts view the move as a shrewd strategic positioning that could yield significant long-term benefits.

“Establishing manufacturing in Australia gives Brabus a unique advantage in the Asia-Pacific luxury market,” explained Automotive Industry Analyst Michelle Park. “They’re effectively cutting shipping times and costs while gaining valuable ‘Made in Australia’ status for regional trade agreements.”

The timing of the announcement also coincides with several automotive industry shifts. With increasing tariffs and shipping costs affecting global trade, localized manufacturing has become more attractive for premium brands seeking to maintain competitive pricing in key growth markets.

For Australian consumers, the local production will likely mean more accessible servicing and potentially more competitive pricing on Brabus vehicles, which have traditionally commanded significant premiums due to import costs.

Competitor Response

The announcement has already prompted responses from competitors in the high-performance luxury space. Industry sources suggest other European tuning houses are now evaluating similar expansion opportunities in the region, potentially creating a new hub for specialized automotive manufacturing.

“Brabus has always been a trendsetter,” noted Automotive Journalist Richard Bennett. “Their move into Australia could be the first of several similar announcements as premium brands look to establish footholds in the Asia-Pacific region.”

This potential clustering effect could further enhance Western Australia’s position as an emerging center for specialized automotive manufacturing, creating additional opportunities for supporting businesses and supply chain development.

Timeline and Future Prospects

The project timeline envisions construction beginning in early 2026, with the first Australian-made Brabus vehicles rolling off the production line by the fourth quarter of that year. The company has indicated that full production capacity should be reached by mid-2027.

Initial production targets are modest, with approximately 2,500 vehicles annually during the first phase of operations. However, the facility design includes provisions for future expansion that could potentially double this capacity as demand warrants.

Beyond the immediate production plans, Brabus executives hinted at broader ambitions for the Australian operation. These include potential expansion into additional vehicle categories and the possibility of Australia-specific limited editions that capture the unique character of the Australian automotive culture.

Local Partnerships

An interesting component of the announcement was the revelation of several local partnerships that will support the new operation. These include agreements with Australian suppliers for certain components and finishing materials, including locally-sourced leathers and timber accents for vehicle interiors.

“We’re excited to incorporate distinctly Australian elements into our vehicles,” explained Brabus Design Director Elena Schulz. “This facility isn’t just about making the same cars in a different location—it’s about creating something that genuinely reflects its environment.”

These partnerships extend to logistics and distribution arrangements that will streamline the delivery of components and the export of finished vehicles. The company has secured priority arrangements at the Port of Fremantle that will facilitate efficient shipping operations throughout the region.

Data: Brabus Australia Operations Projections

| Category | Initial Phase (2026-2027) | Full Operation (2028+) |

|---|---|---|

| Annual Production Capacity | 2,500 vehicles | 5,000+ vehicles |

| Employment (Direct) | 350 positions | 500+ positions |

| Investment Value | AUD 215 million | AUD 300+ million |

| Export Markets Served | 8 countries | 12+ countries |

| Local Component Sourcing | 25% | 40%+ target |

| Training Program Participants | 75 annually | 120+ annually |

| Research Projects | 3 initial programs | 8+ ongoing programs |

Community Engagement and Social Impact

Beyond the economic implications, Brabus has outlined plans for community engagement initiatives to ensure the company becomes a positive force in Western Australia. These include scholarship programs for automotive engineering students, apprenticeship opportunities, and support for local STEM education initiatives.

“We don’t just want to operate in this community—we want to be part of it,” emphasized Buschmann. This philosophy extends to the architectural design of the facility itself, which will include public viewing areas where visitors can observe the production process and learn about the company’s history and values.

The company has also committed to working with Indigenous business partners and ensuring employment opportunities are accessible to all segments of the community. These efforts reflect a recognition that successful global operations require strong local relationships.

Long-term Vision

Perhaps most significantly, Brabus executives described the Perth facility as just the first step in a broader Asia-Pacific strategy. While specific details remain confidential, the company’s statements suggest potential future facilities in other key markets as part of a decade-long expansion plan.

“Australia is the perfect starting point for our global manufacturing evolution,” concluded Buschmann. “The skills, infrastructure, and business environment here provide the ideal foundation for what we envision as a transformative period in our company’s history.”

For Western Australia, the announcement represents both immediate economic benefits and longer-term potential as a center for specialized automotive manufacturing. With construction set to begin next year, the countdown to the first Australian-made Brabus has officially begun.

Short FAQs

When will the Brabus Australia plant begin operating?

The Perth facility is scheduled to begin production in late 2026, with full operational capacity expected by mid-2027.

How many jobs will the new facility create?

The plant will create approximately 350 direct jobs initially, with potential expansion to 500+ positions once fully operational.

Which Brabus models will be manufactured in Australia?

Initial production will focus on Brabus versions of Smart electric vehicles, select Mercedes-Benz SUVs, and Brabus Marine products.

Will Australian-made Brabus vehicles be exported?

Yes, the Perth facility will serve as a manufacturing and export hub for the entire Asia-Pacific region, initially serving 8 countries.

Does this expansion include research and development?

Yes, the facility will include a dedicated R&D center focused on electric vehicle performance technology and regional product adaptations.